Specific materials

& innovation

Specific materials

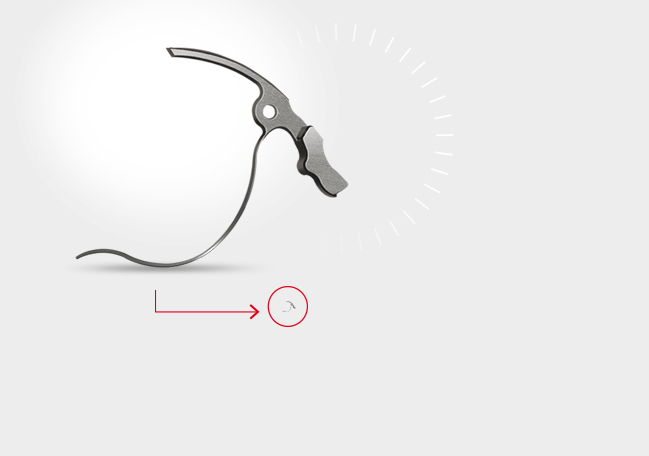

- • Natural materials: wood, horn ...

- • Minerals: ruby, sapphire ...

- • Glass

- • Composite materials: carbon of our manufacture

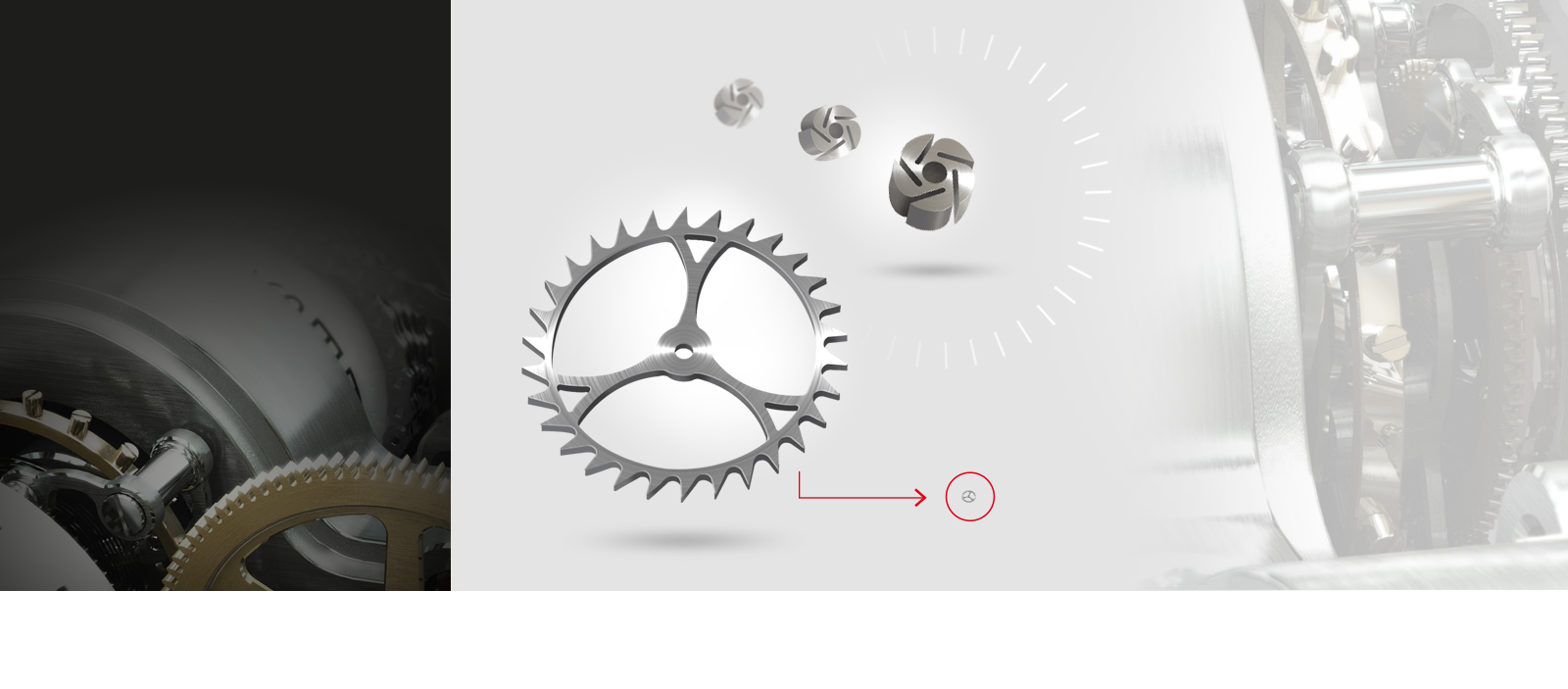

- • Tungsten carbide (possibility of milling)

- • All steels treated or not: titanium, stainless steel, high speed steel, brass, aluminum ...

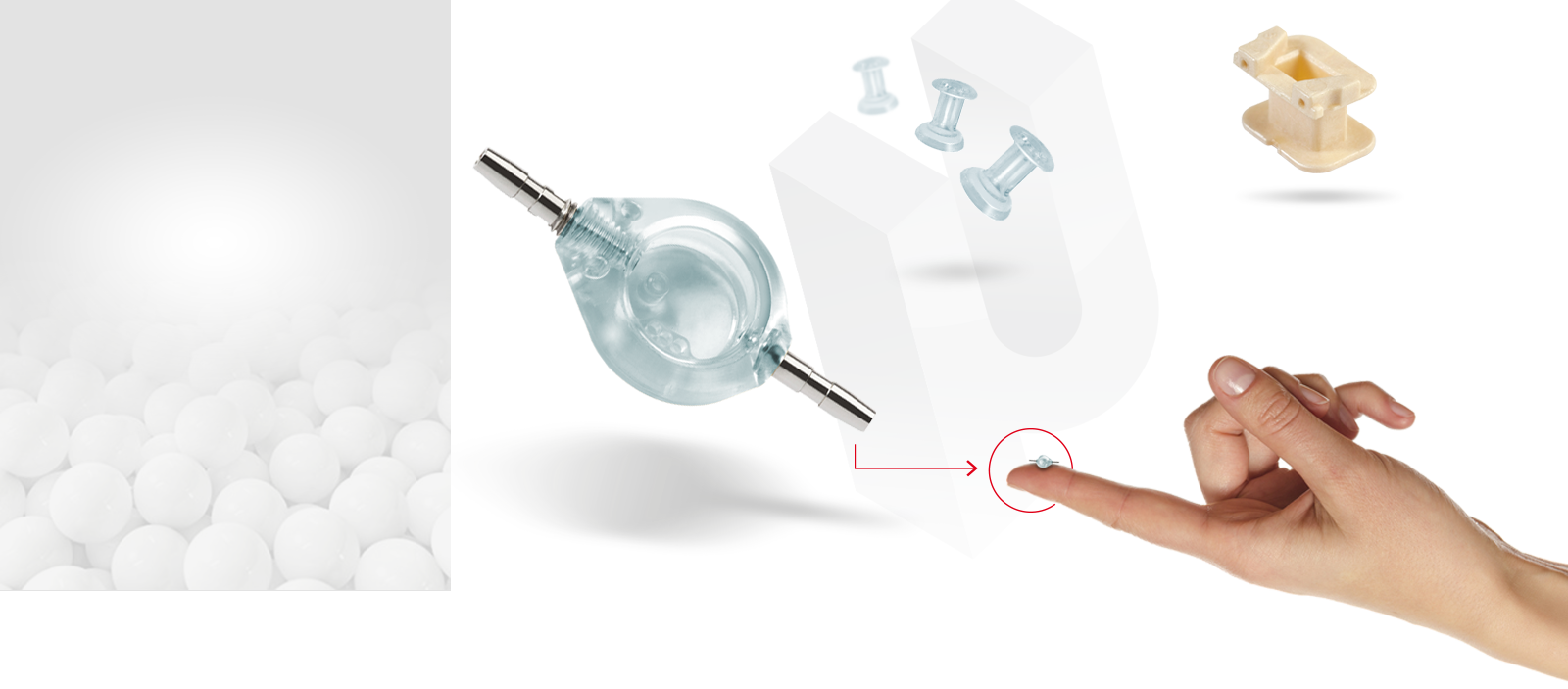

- • All polymers: PEEK, LCP, PSU, POM, galalite, nylon ...

- • These materials can be machined to accuracies of ± 1 micron

Innovation

The Vuillermoz company collaborates with national and international projects

See example below

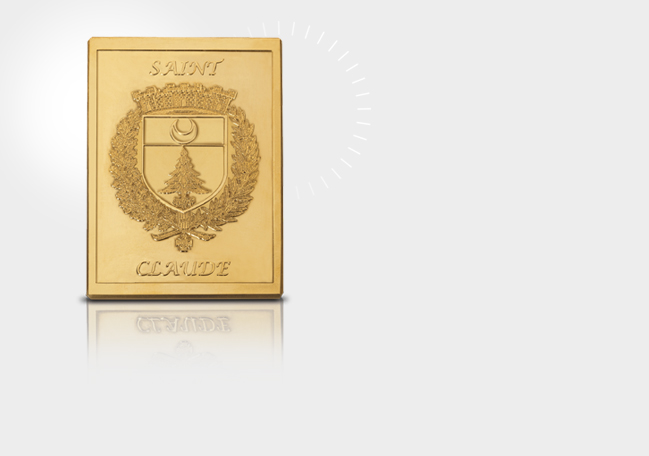

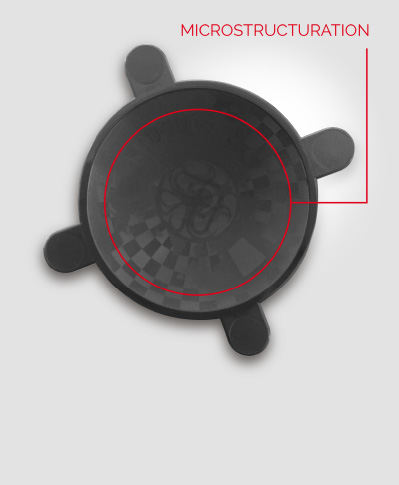

Watch glass micro-structuring to fight against forgery