An Introduction to Magnetic Proximity Sensors

By Tanios BouRamia | July 30, 2021

By Tanios BouRamia | July 30, 2021

Ideal Applications for Magnetic Proximity Sensors

Magnetic proximity sensors are a proven and popular choice for many types of applications. They are often used to monitor the open or closed status of windows, doors, gates, trunks, containers, remote dropboxes, and more in security, monitoring, and anti-tampering type applications. In industrial automation, they can serve as limit switches for actuators. Basically, magnetic proximity sensors are a first class solution for any application where there is a need to monitor the relative position of a moving surface (e.g. a door, window, carriage, gate, lid, etc…). The magnet inside its housing can be attached to the moving surface while the sensor assembly can be installed on an adjoining fixed surface such that when the moving surface is close to the fixed surface, the sensor is triggered and alerts a microprocessor or some other computational unit that the assembly is aligned.

The simplicity of design and function is translating into new applications and use cases for these types of sensors. Historically, remote installations like fuel depots, drop boxes, or other similar points of access would be otherwise unmonitored, secured perhaps with little more than a lock and key or passcode. There was no way to know if anyone had actually been to the locations, taken or left anything, or otherwise gained access without someone physically visiting the site and viewing it directly. The addition of a proximity sensor system with remote communication capabilities can send an alert when a triggering event occurs. This has huge cost savings over the life of the system as it saves time, personnel, and potentially asset loss for the system owners by avoiding unnecessary trips and responding in a more timely way only when actually necessary.

Why Magnetic Proximity Sensors Beat Out the Competition

Magnetic Proximity Sensors have a number of innate advantages that make them superior to other sensing solutions. They aren’t affected by dust, dirt, oil, grease, water, or other contaminants that can foul up capacitive and optical sensors. The magnetic field permeates freely through plastic and non-ferrous metals, allowing for sensing even across hermetic barriers. Finally, they do not require an active supply voltage to operate, simplifying design complexity, reducing overall cost, and minimizing power consumption in battery-powered applications.

Important Factors to Consider Designing in Magnetic Proximity Sensors

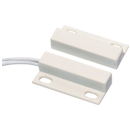

When designing in a magnetic proximity sensor, there are a few aspects to consider. The first is to understand the physical space in which the sensor and magnet will reside. Ideally, you want the magnet housing and sensor housing to align in parallel with one another when the magnet is in the “close” position to the sensor. This will ensure the maximum magnetic field strength is presented to the sensor so that it closes strongly, avoiding a “soft” closure that can impact overall sensor life. Depending on the control circuit scheme the application requires, either a Form A “normally open” single pole single throw (SPST) type of switch or a Form C “changeover” single pole double throw (SPDT) type of switch will be needed. If the sensor is being used outdoors or otherwise exposed to particularly harsh environments, a more robust housing solution may be necessary, including possible sheathing of the wiring exiting from the sensor housing.

Final Thoughts

Magnetic proximity sensors are ideal for a number of different applications and beat out the competition with several innate advantages. C&K is proud to offer the MPS series and the MPSR series of sensor solutions depending on the application requirements. The MPS is simple to install and ideal for indoor installations. The MPSR offers simple installation as well along with added ruggedization that makes it perfect for outdoor and particularly dirty environments where it’s aluminum housing and stainless steel wire sheath provide an extra level of protection against the elements. If you’re facing technical challenges, C&K offers unparalleled support to help you find the right solution. We offer both standard and customized solutions to fit every application.

For more information on Magnetic Proximity Sensors, please check out our Application Note.